In the dynamic world of manufacturing, maintaining or increasing efficiency throughout the evolution of a factory is paramount in a growing production business. This is where as-built plant layout plans and Building Information Models (BIM) are pivotal in helping line engineers and production managers. Knowing all of the exact measurements of your building and its installed equipment are not just tools for organization; they are necessary for calculated growth. The advent of 3D laser scanning has revolutionized how these layouts are captured and plans are created or updated. With the ability to expediently measure existing facilities with astounding accuracy, 3D laser scanning ensures that every square inch of a factory is accounted for, paving the way for seamless integration of new equipment and optimized use of space. Factories that use 3D scanning and as-built modeling firms have a competitive advantage over others, knowing exactly what equipment is installed where, and the ability to quickly configure the most efficient new layouts when new equipment or space is added.

Every Building Element And All Equipment At Your Fingertips

It All Starts With A 3D Scan

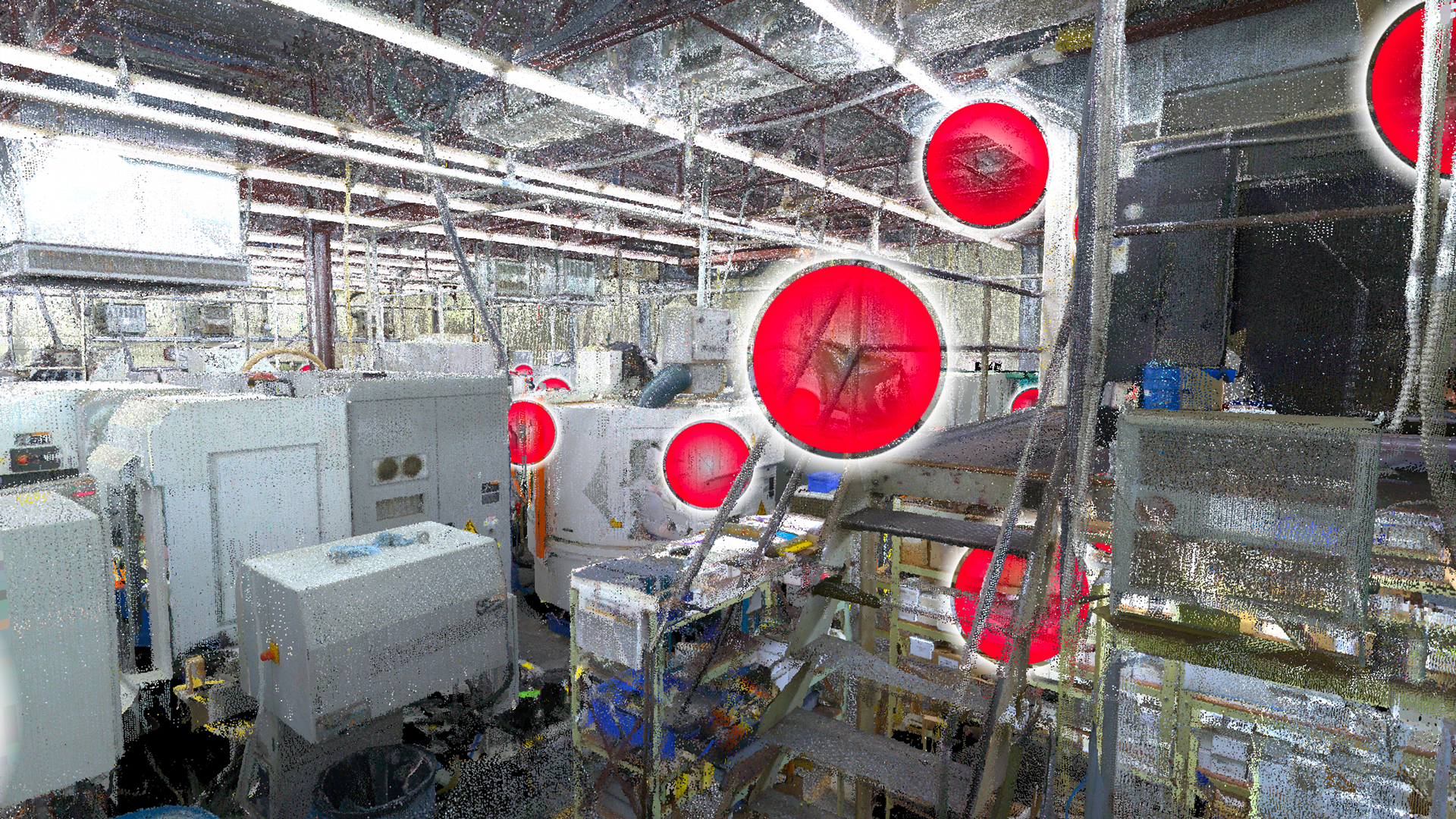

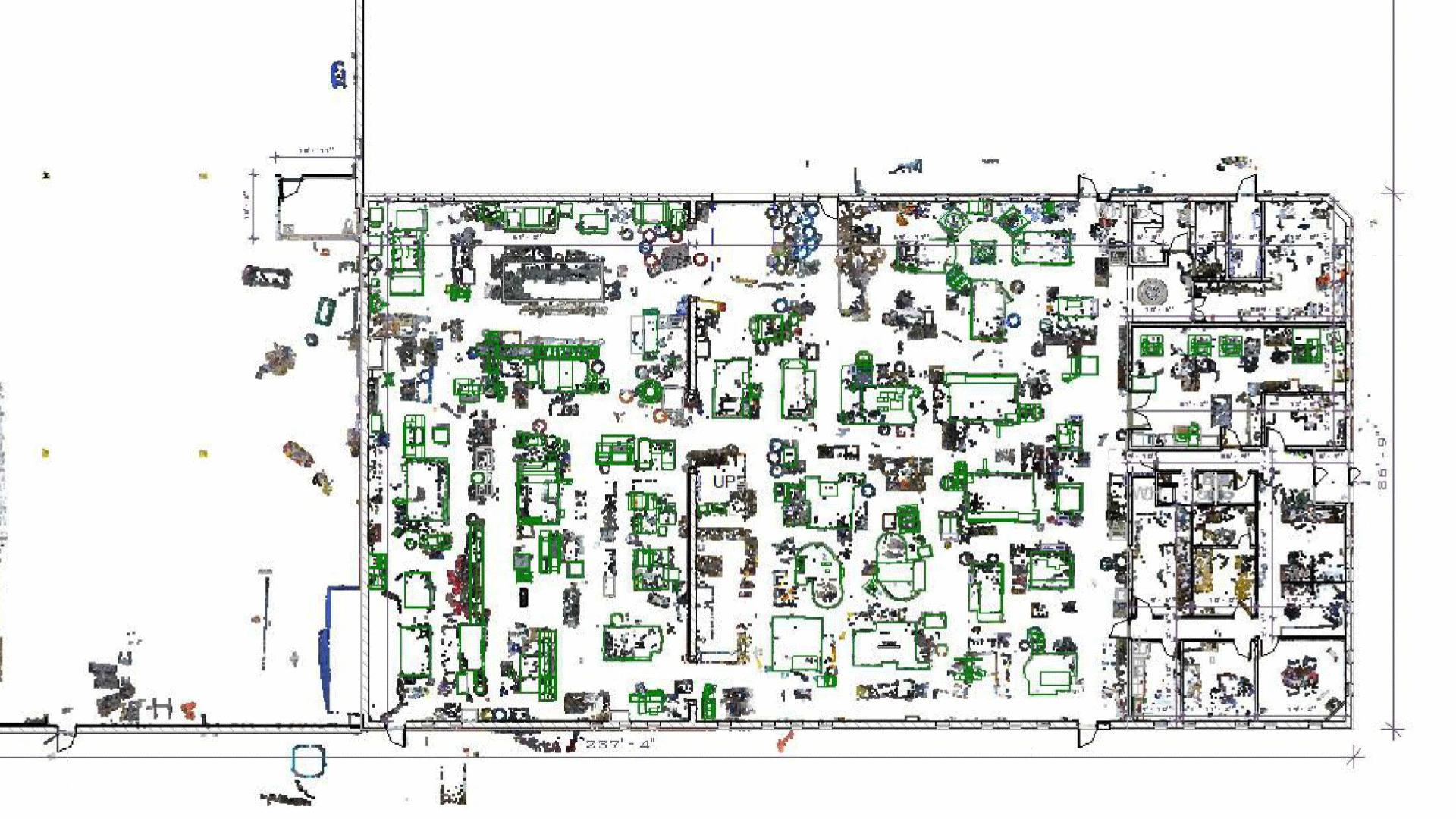

Using 3D laser scanning, we are able to quickly gather all the visual and measurement details required to develop as-built plant layout drawings. The 3D scan uses Terrestrial Laser Scanners (TLS) that measure every millimeter of an existing plant and its installed equipment. In addition to the measurement data, 360-degree photos are also taken to create a virtual tour. In most cases, the on-site capture process is non-invasive and doesn’t require a plant shutdown. Regular operations can be ongoing while the 3D scan is taking place.

The 3D scanning creates a pointcloud file, which contains all the spatial measurement data and 360-photos. This file can be kept offline by any project stakeholder and viewed as a virtual tour. Spot measurement can also be taken using the pointcloud file.

Then The As-Built Plans Are Created

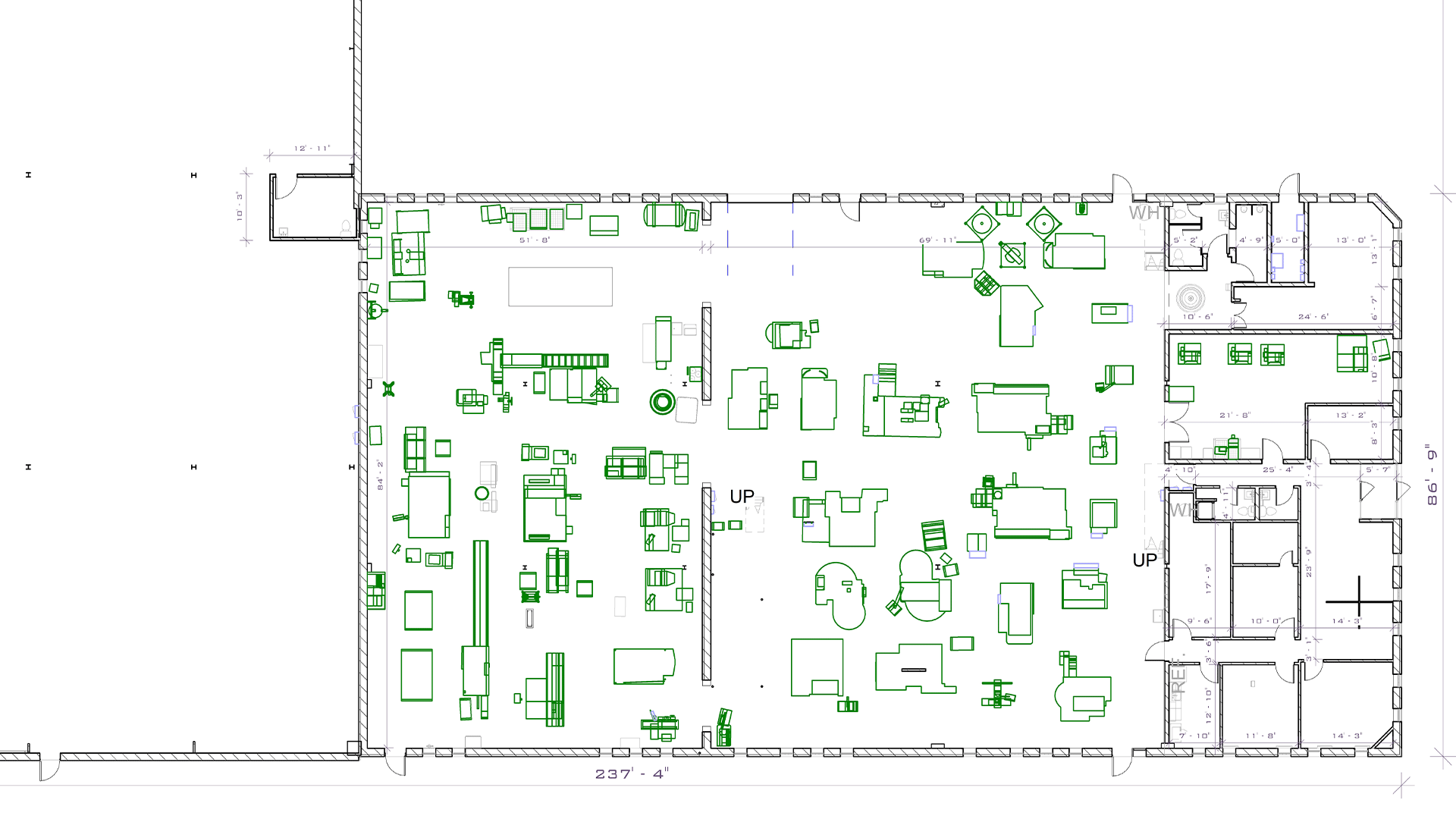

With the pointcloud, all measurement and visual data is available to our architectural drafters remotely – so no secondary visits are required to develop accurate plant layout drawings.

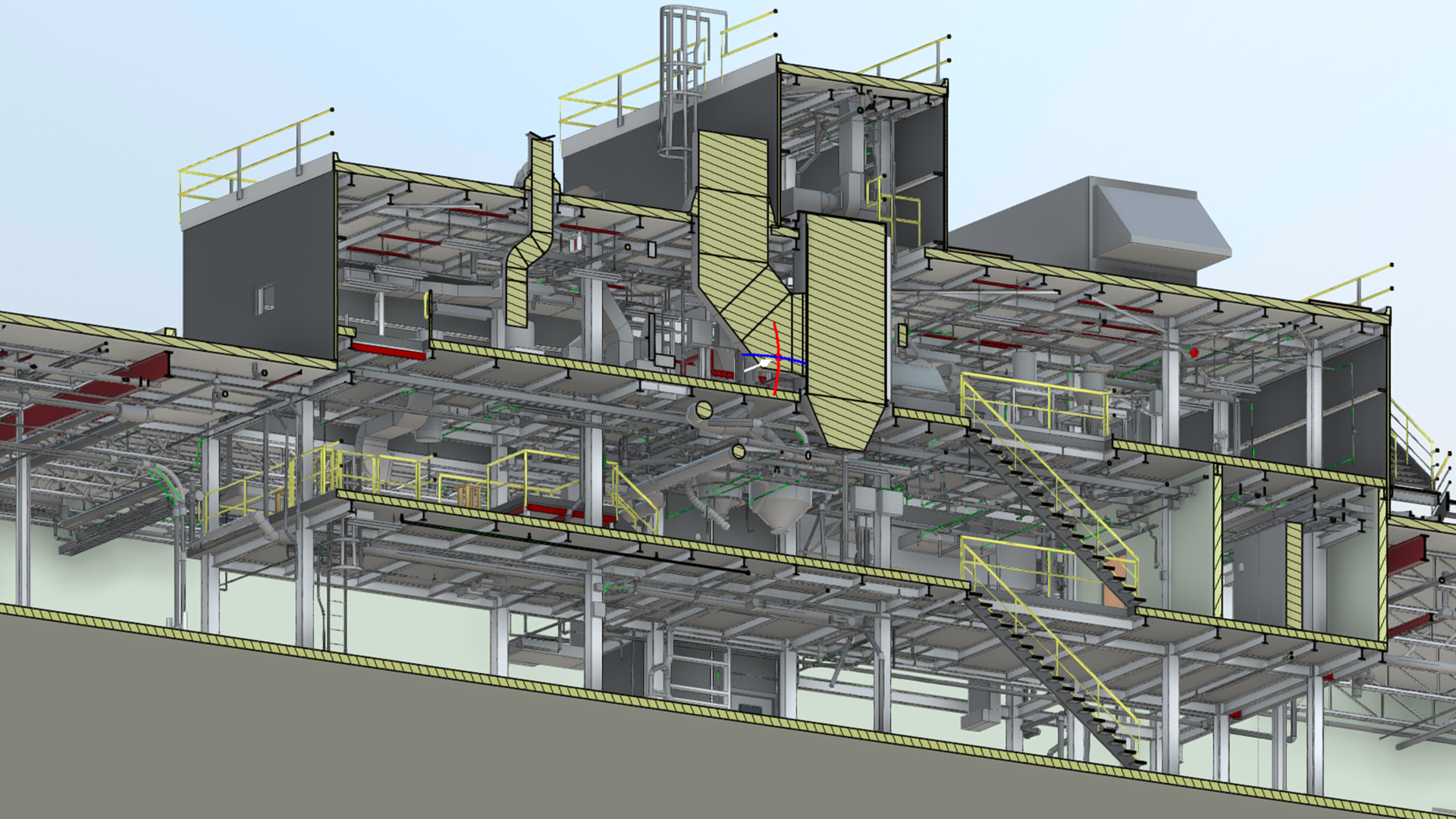

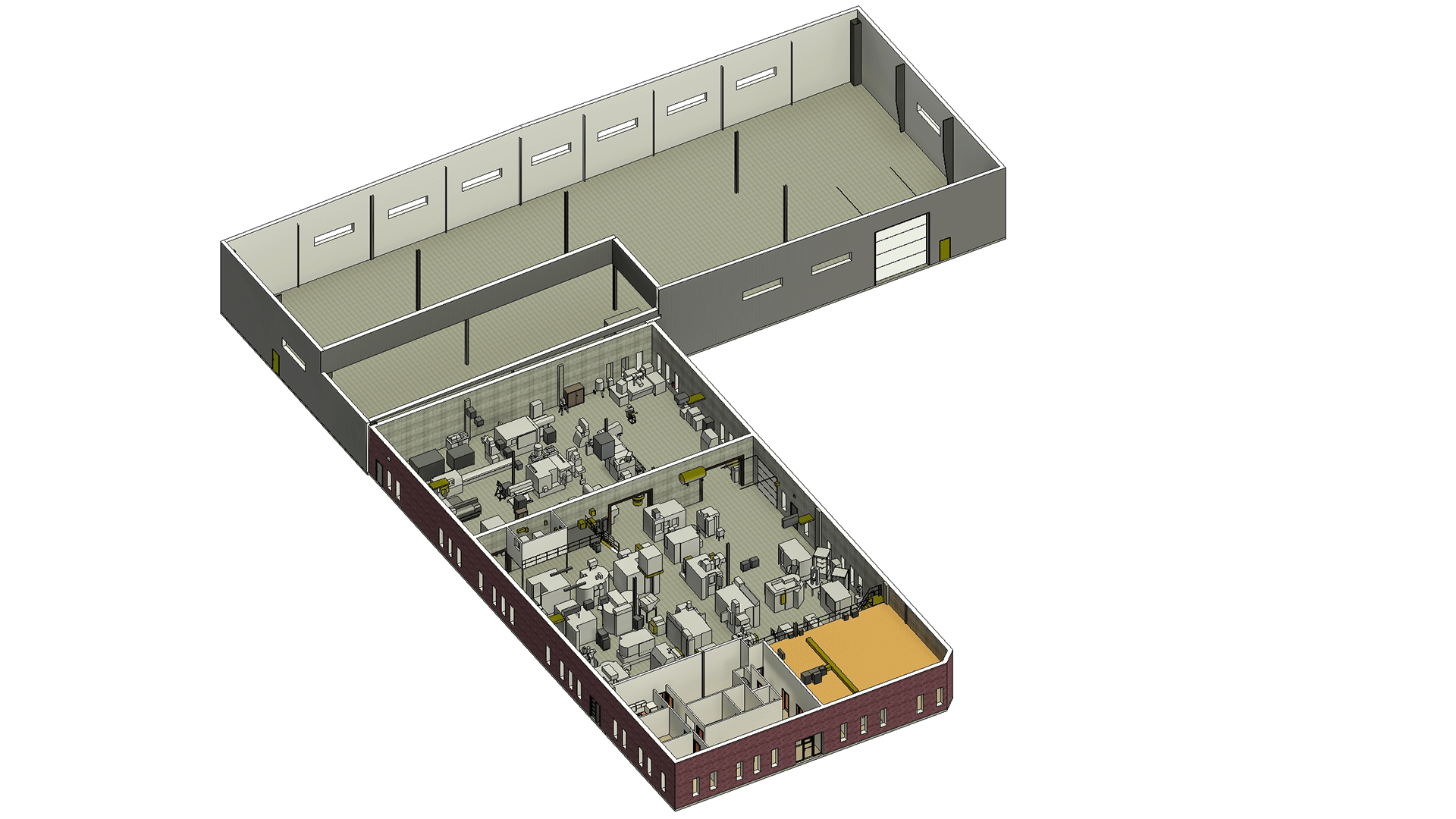

In a well-developed Building Information Model (BIM), all architectural and structural building components are present. After adding the installed equipment all the plans can be created in CAD and PDF formats. We can export floorplans, reflective ceiling plans, elevations, and section drawings from a BIM.

Enhanced Space Utilization

By providing a detailed and accurate view of the current factory layout, plant layout drawings enable engineers and production managers to identify underused areas or potential bottlenecks. This leads to smarter space planning, essential for accommodating new machinery or optimizing workflows.

Streamlined Communication and Planning

Together, the pointcloud file and detailed plans serve as a common language among different departments. Engineers, production managers, and maintenance teams can work in unison, as these plans offer a clear and comprehensive view of the factory’s current state and future upgrades. This synchronicity is crucial for minimizing downtime during expansions or reconfigurations.

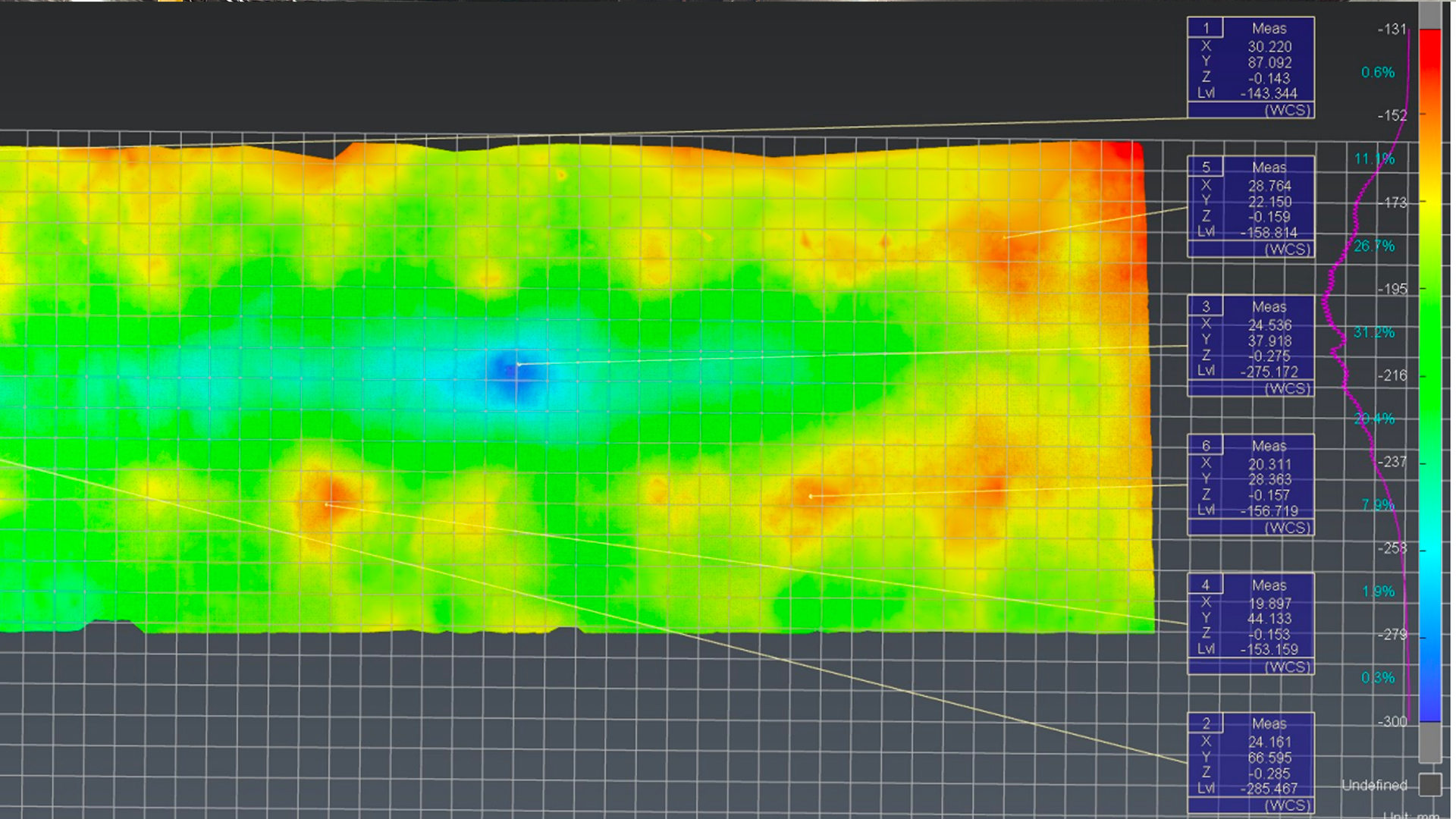

Improved Safety and Compliance

Safety is paramount in factory settings. Detailed layout plans and BIM, developed through precise 3D scans, ensure that new installations comply with safety standards and regulations before installation takes place. They also help in creating safer workflows and emergency egress, enhancing overall workplace safety. As a quick example, even an unlevel floor from repetitious forklift use can cause unforeseen issues and injuries. With 3D laser scanning, floor levelness can be determined and addressed clearly and quickly.

Every Factory Should Be 3D Scanned

In essence, the integration of plant layout plans and BIM, empowered by 3D laser scanning, is not just about adapting to the present; it’s about future-proofing factories. It allows for a level of precision and foresight previously unattainable, fostering environments where innovation is not just possible but encouraged. For factories, this marks a significant leap towards operational excellence, ensuring they not only meet today’s demands but are prepared for tomorrow’s challenges.

Ontario’s Leading As-Built Plant Layout Provider

Contact us today to explore how 3D Laser Scanning can expedite the growth or reconfiguration of your factory and have a competitive advantage over other operators. We’re always excited to hear from different industries. We work throughout the Ontario and Quebec regions.